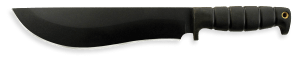

Ontario Knife Company SP-53 Bolo Knife

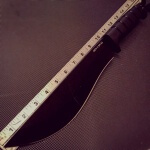

I met the folks from OKC at Shotshow 2015 and was immediately smitten with the variety of tough looking blades on display. We had a few months of back and forth and decided to take a look at the SP-53 Bolo Knife. Looking at the SP-53 on the website or on paper, you see stats like 15 inches overall and 10 inch blade and you feel as if you have a handle on the presence of this knife; but you just don’t.

After the subject was no longer top of mind, I got a delivery and once I opened the long box, wow. I was impressed. The SP-53 is a beast and having it in hand you truly begin to understand how massive this knife is. While the size is impressive, the first thing I noticed was the quality. The SP-53 looks like the hardcore offspring of a TOPS blade and a KA-BAR grip. The blade has the black powder coating you usually only see on high end knives.  (Many companies use a powder coat but there is something different and recognizable about the high end products.) The blade is substantial, literally, it’s slightly over a quarter inch in thickness.

(Many companies use a powder coat but there is something different and recognizable about the high end products.) The blade is substantial, literally, it’s slightly over a quarter inch in thickness. It’s made for work, hard work, and not just a show piece for a weekend warrior. OKC used 5160 steel in this one and while I know it was tough I soon learned how tough it can be.

It’s made for work, hard work, and not just a show piece for a weekend warrior. OKC used 5160 steel in this one and while I know it was tough I soon learned how tough it can be.

In hand, the SP-53 is front weighted for chopping thanks to the blade’s two inch thickness and ten inch length.

and ten inch length. Even so, it’s by no means unwieldy. It’s perfectly suited for chopping, baton work, and finer tasks like feather sticking. If I wanted to make any changes I may make the rounded choil a little larger for added comfort with small tasks.

Even so, it’s by no means unwieldy. It’s perfectly suited for chopping, baton work, and finer tasks like feather sticking. If I wanted to make any changes I may make the rounded choil a little larger for added comfort with small tasks. I would consider a micarta handle, though this would lose the contours that act as hand guards front and back. Lastly, I may consider some extra contour to the back of the tip to allow for easier piercing. However, this too may not be the best idea, since 5160 steel is so hard maybe thinning the tip could lead to a possible fracture in a tough task. That hardness also has another trade to consider, the edge retention of 5160 is legendary so it will undoubtedly give long sharp service. The down side, it’s very tough to sharpen. Plan to spend more time with your sharpener when the time comes.

I would consider a micarta handle, though this would lose the contours that act as hand guards front and back. Lastly, I may consider some extra contour to the back of the tip to allow for easier piercing. However, this too may not be the best idea, since 5160 steel is so hard maybe thinning the tip could lead to a possible fracture in a tough task. That hardness also has another trade to consider, the edge retention of 5160 is legendary so it will undoubtedly give long sharp service. The down side, it’s very tough to sharpen. Plan to spend more time with your sharpener when the time comes.

In my research on this knife I asked a few questions and decided the answers, which came straight from the designer, should be shared unchanged:

1. Material- I started experimenting with 5160 steel in the 1990’s when I was trying to find a material that was tougher (for longer blades like swords) and easier to heat treat in an industrial environment than the 1095 and W-1 and W-2 that I had been using as a custom knife maker. 5160 is an alloy steel which has approximately 0.60% carbon, enough carbon to fully harden the blade and produce lathe martensite (the toughest form of martensite) and not have excess carbides which can embrittle the steel. The additional alloys also improve steel toughness and give the steel a slower cooling profile than the plain carbon steels (1095, W-1 and W-2) which help in production heat treatment. The 5160 steel used in the SP-53 is American made and very clean and refined.

2. Heat Treatment- At about the same time I started experimenting with tougher steels I also purchased a digitally controlled electric kiln and built an agitated quench tank to simulate an industrial heat treatment set up. I ground blades, heat treated them with a variety of austenitizing temperatures and tempering temperatures (resulting in a variety of blade hardnesses), had the microstructures examined and documented by a metallurgist and tested the blades for edge holding and toughness. I ultimately found the best combination of heat treating variables and hardness (Rc 53-55) and brought the heat treatment procedure to Ontario Knife Company for my blades.

3. Design- I had been studying the Filipino martial arts and collecting Filipino edged tools and weapons from the mid-80’s to mid-1990’s which allowed me the chance to develop knife handling techniques and an understanding of how edged tools and weapons really worked. I also purchased a 1909 military bolo in the early 1990’s which I really liked but had a few design flaws, most notably a single beveled edge, which I thought could be improved upon. When I designed the SP-53 I scaled down the 1909 bolo and incorporated features which I liked about the traditional Filipino large chopping knives (symmetrical full bevel grind, strong “weight forward” balance).

I would say it’s interesting insight into the SP-53.

Included with the SP-53 is a very versatile nylon sheath. It has adjustable double snaps for retention. For normal belt wear, it has grommets for a leg tie down. It’s also fully MOLLE compatible and sports a generous front pouch for accessories like sharpeners or ferro rods.

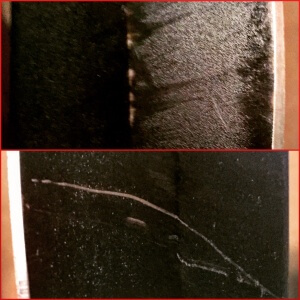

As for my experience, it was all quite positive. From the people at OKC to the immediate perceived quality of the product to my work leading to a surprising bit of baton work. As seen in my video, while doing a light baton task I inadvertently cut through at least one hidden nail. You can see in the video that there was practically no effort involved in the task. While my fumble clearly damaged the powder coat finish the blade edge came through the task with a near imperceptible mark; I could barely identify the point of contact. In fact, showing others took magnification. The 5160 steel is truly impressive!

The 5160 steel is truly impressive!

On top of everything else the price point is awesome. You can buy an OKC SP-53 Bolo Knife on Amazon for $82.02 as of the time of writing this review. That is a crazy deal for this size, steel, quality and craftsmanship. I would recommend it to anyone without hesitation.

>

Yes I have the okc sp53. What a chopper! It I had to choose only one knife this would be it. It will get you out of any extreme situation you don’t want to be in. Highest Recommend. Get One..